Consumers across the country rely on the wireless industry to stay connected to their family, friends, jobs and entertainment.

Due to the proliferation of data transfers between cellular and connected devices, increase in number of devices, and the demand for broader network coverage communication carriers are scrambling to serve this growing market. KCI supports several national carriers by building and deploying small cells to increase connectivity in cities and towns across the country.

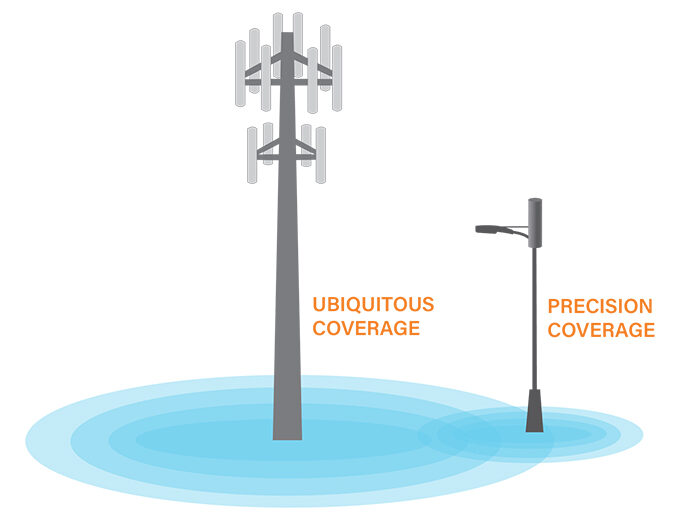

When most people think of cellular, they picture tall monopole or guyed towers supporting an array of antennas. These sites, also known as macrocells, provide low frequency coverage for a large geographic area. The amount of data that these signals can carry is limited based on strength, type and quantity of equipment on the tower. As the number of connected devices continues to grow and the volume of data being consumed increases, these limitations can result in slower speeds and sporadic connections. To increase capacity, especially in densely populated areas, additional wireless equipment, closer spacing of sites and higher frequencies are required.

KCI’s Communications Infrastructure team supports the entire project lifecycle, from permitting through construction and closeout for the deployment of small cell networks. Radio equipment and antennas are attached to existing and new structures like streetlights and utility poles in the public rights-of-way. Located closer to a user’s device and connected by fiber optic cable, small cells complement existing wireless networks by providing enhanced capacity and performance to densely populated areas of a community.

Installation of a small cell first requires identifying a site and then obtaining the necessary right-of-way and electrical permits to power and place the technology. Existing utilities must be identified and marked to avoid potential and costly delays. Materials and equipment are kept in inventory at KCI’s warehouses and yards, which are strategically located in Maryland, Virginia and Florida to support work across the eastern seaboard. This includes the firm’s new state-of-the-art technology center in White Marsh, Maryland, which was designed specifically to expedite the assembly of wireless infrastructure.

KCI’s new technology center was designed specifically for the storage, equipment and workstations required to optimize small cell assembly.

KCI’s new technology center was designed specifically for the storage, equipment and workstations required to optimize small cell assembly.The 50,000 square-foot facility features material racks and cages that offer technicians easy access to needed supplies. For small cell pole buildouts and upgrades, our team uses specialized equipment and workstations so that the components can be fit out in an assembly line fashion. Adjustable pipe jack stands with wheels help to maneuver poles from one workspace to the next, where crews run all required cabling and install meters, load centers and antennas. Once tested, completed poles are stored on special racks. Assembly inside our technology center significantly improves efficiency, quality and safety by creating a controlled environment that is customized to the needs of that specific carrier.

Crews have been able to increase production of small cell build-outs while significantly cutting assembly time.

Crews have been able to increase production of small cell build-outs while significantly cutting assembly time.While the small cell equipment is readied, preparation begins on site for installation. Existing streetlights must be deenergized. Concrete or asphalt may need to be cut and trenched to expose the wiring. New fiber is laid to the location, and old pole foundations are replaced to support the additional loads from the small cell components added to the streetlight. Technicians may also use directional drilling and set new handholes in order to facilitate power and fiber pathway placement and splicing.

“Ninety percent of the work on the pole itself is done in the Technology Center to eliminate potential delays such as weather and reduce time spent coordinating traffic and right-of-way issues in the field.”

– Marty Ayres, Practice Leader

The pole is then delivered from the warehouse and installed. Technicians again test the equipment to ensure proper operation and then complete any restoration work to return the site to its pre-construction appearance.

Since the small cells are fed by fiber, carriers can quickly upgrade technology in the future by swapping out equipment.

Since the small cells are fed by fiber, carriers can quickly upgrade technology in the future by swapping out equipment.Over the next few years, the number of small cells being deployed is expected to dramatically increase due to the expected growth of 5G and the ongoing evolution of next generation wireless devices. In addition to meeting the demand for greater speed and capacity, these network enhancements will also aid new and emerging technologies that facilitate smart cities and the internet of things.

Learn more about KCI’s innovative Communications Solutions by watching the video below.